Lead

Lead is one of the most used materials for radiation shielding. Due to the high density of lead, it is very effective at reducing radiation exposure from x-rays and gamma rays. Because of the efficient shielding properties and relatively low price, Lead shielding is used in many industries, such as healthcare, nuclear energy, research, security, and many others. Our factory has the production facilities to manufacture our radiation shielding solutions in-house. Shing Shun is your go-to production facility for any radiation shielding or lead related solutions due to our production capabilities and more than 40 years of experience.

LEAD

FAQs

Material Properties

Lead is a soft metal that can be easily scratched or dented. Being ductile and malleable makes lead very easy to work with. It is a very dense metal with a density of 11340kg/m³, approximately 4times the density of aluminum. Lead has a melting point of 327°C which makes it an ideal metal to cast.

Under the principle of standardisation, the Royal Charter established the British Standards Institution (BSI) as an independent body in 1901. UK standardisation rules apply to lead-lining and are maintained by British Standard BS EN 12588, ensuring all lead sheet / lead plate / lead brick is produced to certain specifications and exact chemical compositions. Shing Shun offers high quality, lead product manufactured from BS EN 12588. The lead-lining standards include:

Pure lead: 99.81%

Standard thickness tolerance: +/- 5%

Properties of Lead

Melting Point: 327.5°C (621.5°F)

Density: 11340kg/m³ (Room Temperature)

Atomic Number: 82

Stable Isotopes: 204Pb, 206Pb, 207Pb, 208Pb

Lead is toxic and can accumulate within the body if proper precautions are not taken. Encapsulating the lead in metal, plastic, or paint will greatly reduce the risk of lead exposure.

Lead Attenuation

Lead is very effective at shielding gamma radiation. Because of the density of lead, its high atomic number, and stable isotopes, lead is ideal for stopping gamma and x-ray radiation. For a gamma ray from a Colbalt-60 source, pure lead has a Half-Value Layer (HVL – the thickness of shielding required to reduce the level of radiation by 50%) of approximately 12.5mm (0.49in). A lead shield will be thinner than a steel (21.6HVL) or concrete (60.5HVL) shield of the same effectiveness in shielding a Co60 source. From an x-ray source with a peak voltage of 200 kV, the HVL of lead would be 0.52mm (0.021in).

Lead Processing

Typically lead can come in several different forms. It is common to melt the lead and either cast it in a mold or fill a pre-made fabrication. Lead bricks are an example of a cast lead product. The molten lead is poured into a preheated mold and as the lead cools, the lead shrinks and the casting can be removed from the mold. Lead can also be machined to achieve tighter tolerance than would be possible with just a casting.

Extruding and rolling lead is possible because lead is very malleable. Lead sheet / Lead plate is formed from rolling lead, and is a very useful product for shielding. In x-ray or gamma testing applications, Lead sheet / Lead plate can be easily installed in barriers, walls, and mounted on drywall and plywood. Lead can come as thin as 1mm, making it easy to bend and fold around walls. The most common thicknesses of sheet lead used are 1mm, 2mm, 3mm, and 5mm.

Lead has many uses for radiation protection, from creating lead-lined furniture to small lead vials. Because of its availability, price, and the ability to form, cast, or machine, lead can be made into any radiation shielding product that you could want. If you would like to find out more information about lead fabrication and shielding, visit the Shing Shun website or contact Shing Shun directly, and we will help you find the best radiation shielding solution for your needs.

Lead Glass

Lead lined glass is a specialized type of annealed glass that incorporates lead oxide and other heavy metals with the purpose of providing effective protection against radiation by absorbing the energy emitted by the radiation source. This unique lead glass is widely employed in various medical settings, including dentist offices, hospitals, and laboratories where x-rays and other radiation therapies are conducted. Additionally, it finds applications in industrial environments, such as x-ray imaging of welds on airplanes and pipelines.

LEAD GLASS FAQs

Product Properties

Though the incorporation of lead oxide (up to 65% of the overall weight), our lead glass products achieve the necessary density to deliver radiological protection at a fraction of the thickness of standard plate glass. Along with little or no visual distortion, this has the advantage of providing exceptional visibility of patients undergoing diagnostic procedures or therapeutic treatment.

This is a frequently asked question?

It all begins with an idea. Maybe you want to launch a business. Maybe you want to turn a hobby into something more. Or maybe you have a creative project to share with the world. Whatever it is, the way you tell your story online can make all the difference.

Advantages

High Quality, Transparent Lead Glass. Shing Shun ’s lead glass has been designed to provide a high quality, transparent, protective shield against x-ray radiation. Extensive research and development has been done for you to trust its comprehensive protection in any medical or technical research application.

This is a frequently asked question?

It all begins with an idea. Maybe you want to launch a business. Maybe you want to turn a hobby into something more. Or maybe you have a creative project to share with the world. Whatever it is, the way you tell your story online can make all the difference.

Standard sizes for lead glass

Our x-ray shielding glass is available standard in 1.6mm, 2.0mm, 2.5mm, and 3.2mm equivalencies. We manufacture our high-grade lead-lined glass in accordance with the Lead Industries Handbook and NCRP Applicable Reports to ensure our radiation protection supplies meet or exceed Federal Specification DD-G-451.

This is a frequently asked question?

It all begins with an idea. Maybe you want to launch a business. Maybe you want to turn a hobby into something more. Or maybe you have a creative project to share with the world. Whatever it is, the way you tell your story online can make all the difference.

Lead Brick

MarShield lead brick shielding provides the best choice for construction where temporary, permanent shields or storage areas are required, offering you the flexibility in your design and construction choices. Lead bricks are ideal for adding additional shielding to existing rooms and can be used in new construction as a method to reduce wall or ceiling thickness to achieve space savings. Our high purity lead bricks are ideal for shielding effectiveness where maximum protection is required from X-Ray and Gamma Ray radiation. Our bricks are relatively smooth, clean and have a non-porous surface. Our lead bricks can be used for walls, caves, glove-boxes, hot cells or partitions, the transportation of radioactive materials, and nuclear shielding or simply as ballast weight. Bricks are available in a wide range of sizes, thicknesses and shapes to suit your application. They are commonly used for shielding when sheet lead is impractical or not available in sizes or thicknesses you may require. Straight or interlocking styles are available from our stock.

LEAD BRICK

FAQs

Interlocking

MarShield offers interlocking Chevron style bricks for maximum protection where the highest level of shielding is required for X-ray Beta and Gamma Shielding.

Can be easily erected, modified, disassemble and relocated in the field to create protective walls systems and cells to suit your application.

Unique interlocking “V” shape tongue and groove configuration prevents the leakage of radiation through gaps as commonly found in straight lead bricks.

Provides a more stable and sturdier wall system aiding in the prevention of the wall toppling over.

An efficient and tighter fit shielding when stacking or building wall systems.

Standard sizes for lead glass

Our x-ray shielding glass is available standard in 1.6mm, 2.0mm, 2.5mm, and 3.2mm equivalencies. We manufacture our high-grade lead-lined glass in accordance with the Lead Industries Handbook and NCRP Applicable Reports to ensure our radiation protection supplies meet or exceed Federal Specification DD-G-451.

Machined and Milled

MarShield offers Machined and Milled lead bricks in standard and custom sizes. Machined and Milled lead bricks are used for shielding radiation for industrial and medical uses, as well as for anti-corrosive linings.

Lead Processing

Typically lead can come in several different forms. It is common to melt the lead and either cast it in a mold or fill a pre-made fabrication. Lead bricks are an example of a cast lead product. The molten lead is poured into a preheated mold and as the lead cools, the lead shrinks and the casting can be removed from the mold. Lead can also be machined to achieve tighter tolerance than would be possible with just a casting. Typically, alloys of lead, such as 2-4% antimonial lead, are easier to machine because the antimony makes the lead harder and less prone to chipping when cut.

Extruding and rolling lead is possible because lead is very malleable. Lead sheet / Lead plate is formed from rolling lead, and is a very useful product for shielding. In x-ray or gamma testing applications, sheets of lead can be easily installed in barriers, walls, and mounted on drywall and plywood. Lead can come as thin as 1/32”, making it easy to bend and fold around walls. The most common thicknesses of sheet lead used are 1/32”, 1/16”, 1/8”, and ¼”.

Lead has many uses for radiation protection, from creating lead-lined furniture to small lead vials. Because of its availability, price, and the ability to form, cast, or machine, lead can be made into any radiation shielding product that you could want. If you would like to find out more information about lead fabrication and shielding, visit the Shing Shun website or contact Shing Shun directly, and we will help you find the best radiation shielding solution for your needs.

2 CONSTRUCTION METHODS

HARD SHELL CAPSULE CLEANROOMS:

Modular cleanrooms / 無塵室 / 潔淨室 are the most prevalent method of contemporary cleanroom construction. They are made of prefabricated cleanroom panels that are manufactured offsite. Proprietary coved corner for easy cleaning.

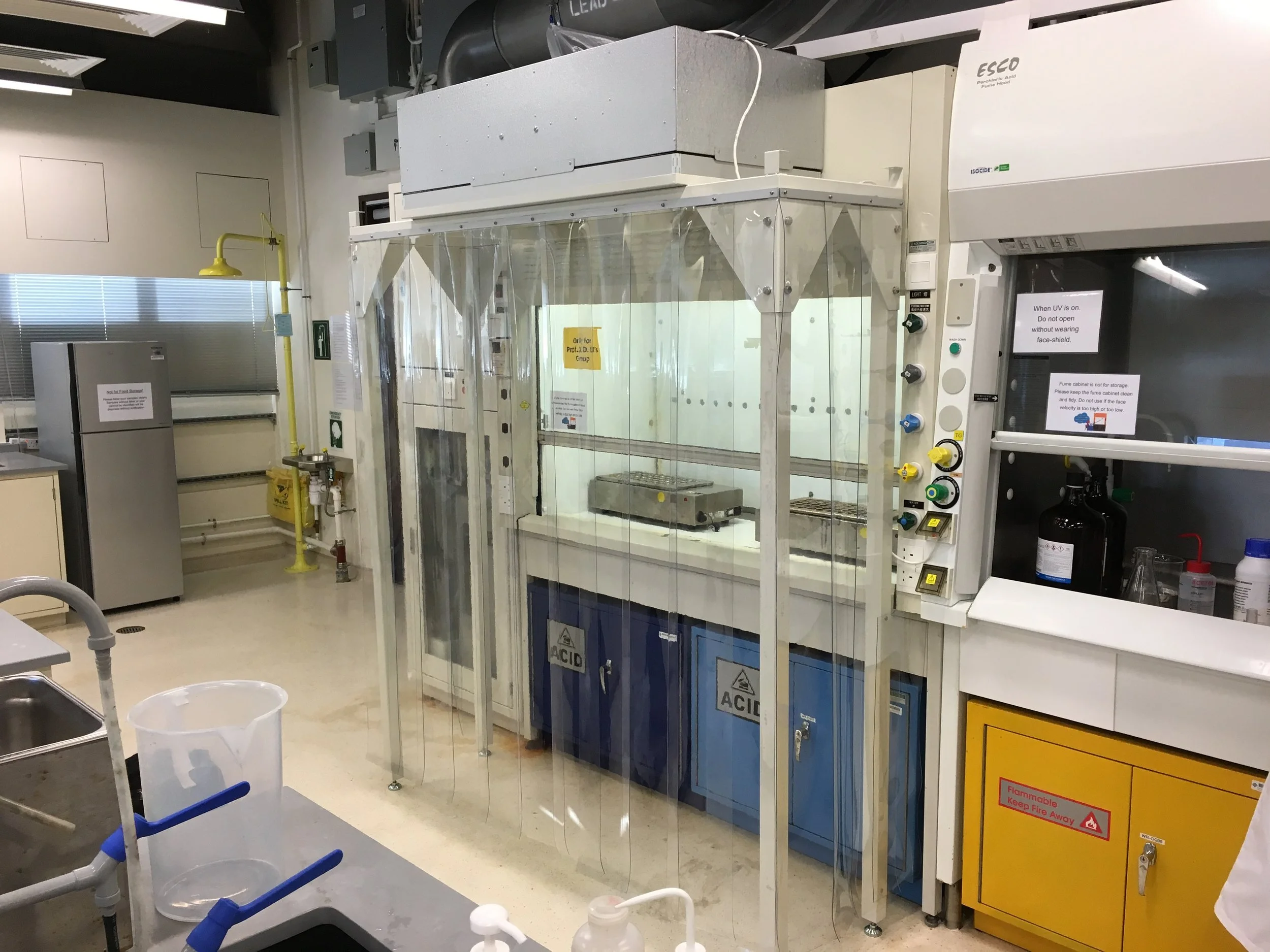

SOFT SHELL CAPSULE CLEAN BOOTHS:

Clean booths / 無塵棚 / 潔淨棚 are enclosures constructed of heavy metal frames suspending overlapping clear, flexible PVC films with special anti-static formulation to create a walled room. These rooms are economical and can be easily moved.

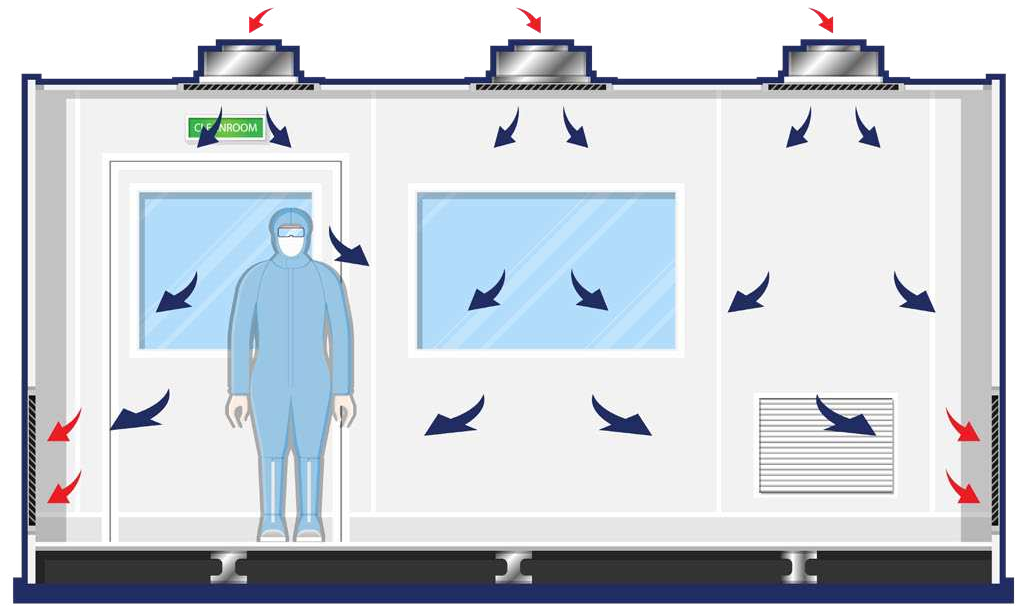

CLEANROOM AIRFLOW

Cleanrooms utilize air pressure, whether positive or negative, to control contaminants entering or leaving the room.

POSITIVE AIR PRESSURE CLEANROOM:

A positive air pressure cleanroom is an enclosure where the internal atmospheric pressure is greater than that of the exterior. This is accomplished by pumping clean air into the room, typically through the room’s ceiling.

Positive air pressure rooms keep contaminants out when a door is opened, as clean air rushes out. The external air is kept from entering the room by the room’s higher barometric pressure.

This can be likened to the air pressure in a bicycle tire. As the air in the tire is under pressure, when you release the tire’s air by depressing the valve, air isforced out, but none is allowed to enter the valve — at least not until the atmospheric pressure in the tire and the external ambient air pressure are equalized.

NEGATIVE AIR PRESSURE CLEANROOM:

A negative air pressure cleanroom is a room where the air pressure inside the room is lower than that of the air outside of the room. This is achieved by forcing air to exit the room through a filtration system. Generally, the air in a negative pressure room enters through filters near the floor and exits through filters in the ceiling or fume hood.

Negative pressure rooms are intended to keep any contaminants from escaping the room unfiltered. These rooms are used to keep harmful particles or contaminants from entering communal air.

CLEANROOM AIRFLOW

LAMINAR AIRFLOW:

Laminar airflow is defined as air that flows in a straight and unimpeded path. Also referred to as unidirectional airflow, cleanrooms utilizing laminar airflow rooms intake air using laminar airflow hoods that direct the airflow straight down to be exhausted through exhaust fans placed in the floor. Designing a laminar airflow cleanroom is a complex task. Ensuring the least amount of turbulence as the air navigates through a room of furniture, devices, and people is a matter of expert engineering and architecture.

NON-UNIDIRECTIONAL AIRFLOW:

Non-unidirectional, or turbulent, airflow rooms use non- linear airflow. This random movement of air helps to separate particles from the air and into the filtration system.

Guidance Notes

on the Design of

Protective Shielding for

Medical, Dental and Veterinary

Diagnostic

X-ray Facilities

Basic Protection Requirements

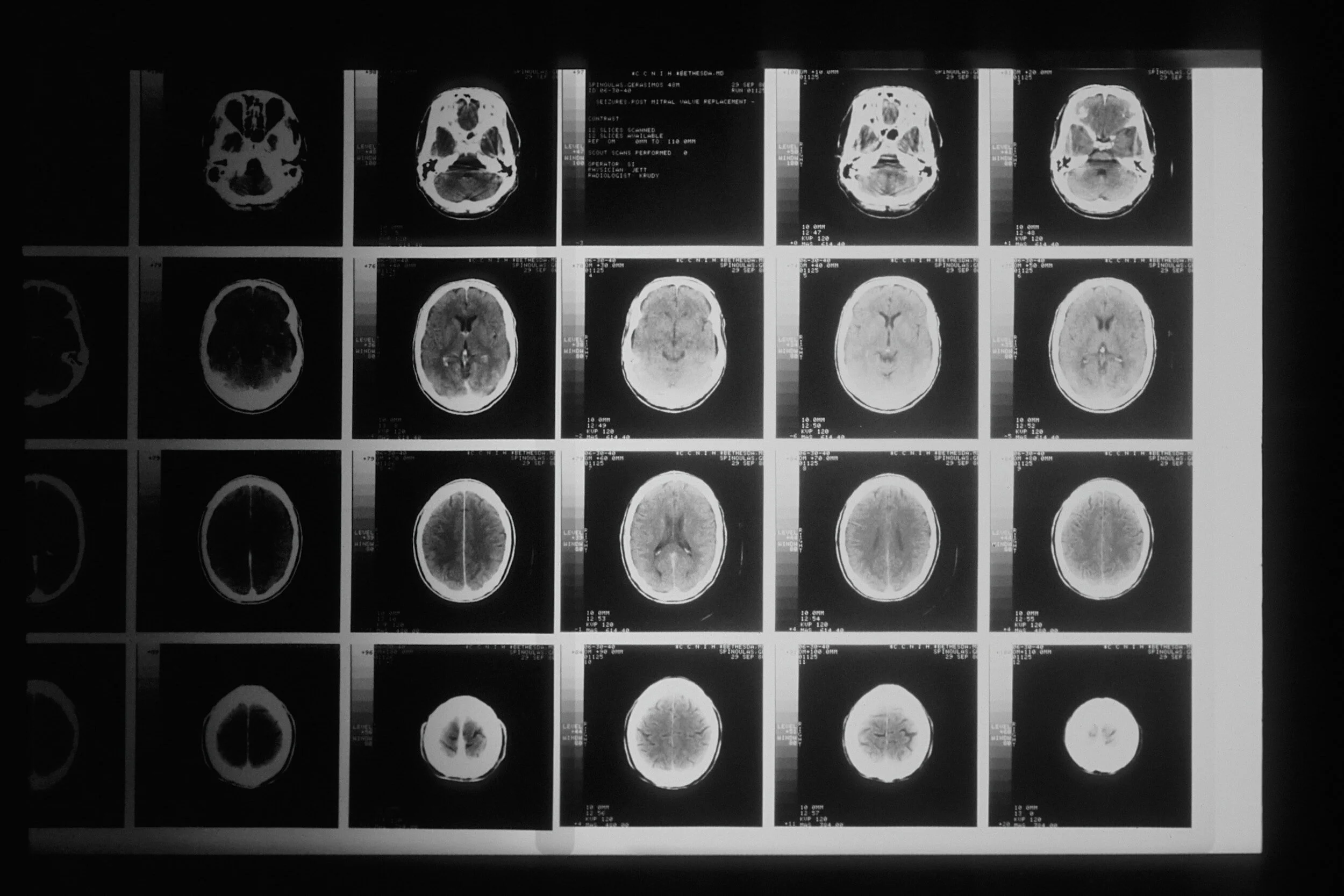

The requirement for protective shielding of a radiological device depends on the type and workload of the device, the energy of the radiation it produces, the size of the room and the occupancy of nearby areas. The requirement is higher for shielding of the direct radiation beam than for shielding of the scattered radiation field. Therefore whereas a dental x-ray room may require a nominal shielding of about 1.5mm lead for the direct beam and about 0.7mm lead for the scattered field, a diagnostic x-ray room may require a nominal shielding of about 3mm and 1.5mm for the direct beam and scattered field respectively. For clay brick and concrete, the equivalent material thicknesses at different x-ray output voltages are given in Table 1. The nominal thicknesses of commercially available lead sheets are given in Table 2.

Protective shielding close to the x-ray head is the most economical arrangement; the thickness is the same, but the area to be covered is smaller. Most x-ray housings have sufficient built-in shielding to limit the radiation mainly to the useful beam passing through the aperture, but it is still necessary to shield against the useful beam itself, the small amount of leakage radiation from the housing, and the scattered radiation from the patient and other irradiated objects such as the floor and walls of the room.

The amount of shielding required depends on a number of factors, including:

a) the x-ray tube voltage

b) the workload: mA-min/week

c) the type of radiation: e.g. useful beam, leakage, or scattered

d) the distance from the radiation source or the scattering source to the occupied area

e) the type of area: controlled or uncontrolled (the latter being open to the general public)

In view of the fact that limited facilities are inevitably called on to take larger workloads, it is highly desirable to plan the protection of an x-ray room for the maximum foreseeable load, allowing for the time taken to arrange patients and carry out the x-ray examination.

In radiography, the useful beam is usually directed towards the floor or the wall. To ensure a high factor of safety, protective shielding against primary radiation is provided on any wall area towards which the useful beam is likely to be directed and on the entire floor. Other areas not routinely exposed to the useful beam require protective shielding against secondary radiation.

However, when building a new x-ray room it is always better to plan for effective shielding against primary radiation in all directions so that there are no further problems when the equipment is moved or changed. Under no circumstances must an area be left unprotected since scattered radiation penetrates in every direction. In private practice where x-ray machines are located in commercial buildings with adjacent rooms being public areas, it is particularly important to ensure that the radiation levels do not exceed the regulatory limits.

Special attention should be given to the protection of the operator. Only licensed users are allowed to operate x-ray machines on human body. Effective shielding will be achieved by locating the control of the x-ray equipment in an adjacent room provided with a lead-lined door. A shielded control booth without a door can be used if access is provided by means of a maze that effectively reduces the scattering of radiation into the control area.

Design of protective shielding

The thickness of protective shielding necessary to reduce the exposure rate from any x-ray machine to the maximum permissible level depends on the tube potential, the extent to which the machine is used (work-load), the distance from the tube to the occupied area, the degree and nature of the 2 occupancy, the type of area, and the material of which the barrier is constructed. Care must be taken to ensure that the required protective barrier is not reduced by openings or voids in the barrier. Guidance for installation of lead lining as protective shielding is given in the following paragraphs.

Joints / Joints at floor and ceiling

-

The possibility of leakage at joints is eliminated by overlapping the protective materials. The amount of overlap required depends on the distance between the layers, the thickness of the shielding, and the relative thickness of the two layers. Fig. 1 shows how the overlapping between lead and concrete can be carried out. The width of overlapping (b) must be at least as great as the thickness of concrete (t). Lead sheets should be jointed to each other with an overlap of at least 1cm or twice the thickness of the sheet, whichever is the greater. Joints between different kinds of protective materials are constructed so that the overall protection of the barrier is not impaired.

The overlap between the lead in the wall and the concrete in the floor or ceiling must have at least the same width as the thickness of concrete (Fig 1A).

Recesses

-

Recesses in the barrier (e.g. for electrical outlets and locks) must be covered to give protection equivalent to that of the required protection barrier (Fig. 2).

Perforations

-

Nails and screws that perforate lead barriers must be covered to give protective equivalent to that of the unperforated barrier (Fig.3).

Doors

-

The radiation facility should be so designed that primary radiation does not strike the door. Since the door is then exposed only to secondary radiation, the threshold may be arranged as a baffle, formed by the lead lining of the door and the concrete in the floor (Fig 4).

Doors

-

The door and door frame must have the same lead equivalence as the adjacent wall. The protective lead covering the door must overlap that of the door frame by at least 1.5cm. The protective lead covering the door frame must overlap the concrete or brick in the wall by at least the same amount as the thickness of the concrete or brick (Fig 5).

Observation window

-

The window and window frame must have the same lead equivalence as that of the adjacent wall. Lead sheets in contact with lead glass must have an overlap of a least 1cm or equal to the thickness of the lead glass, whichever is the greater (Fig. 6).